Choke & Kill Manifolds

Choke & Kill Manifolds

- Product description: All choke and kill manifolds and their component parts are manufactured under highly regulated industry product design and type approvals. All systems are fully certified in accordance with industry r

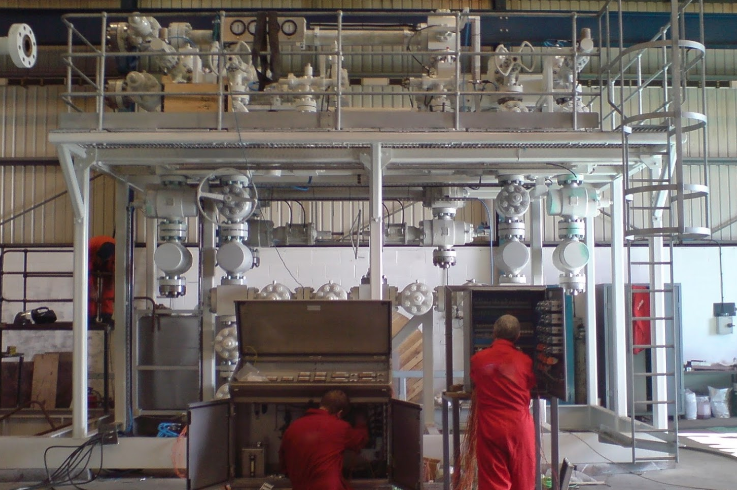

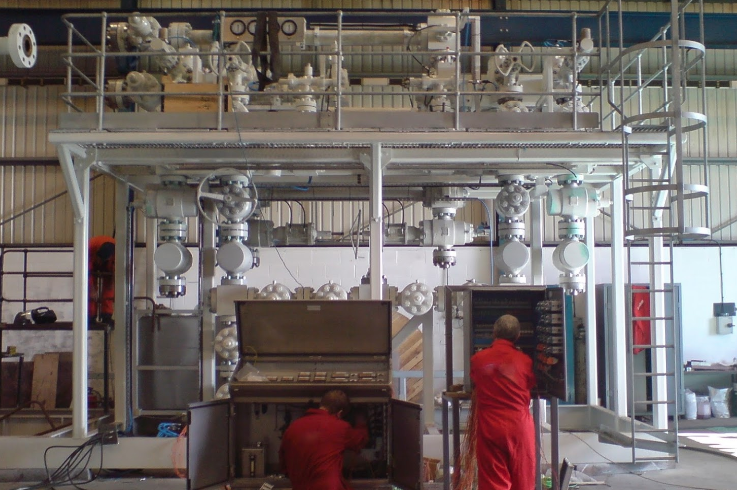

Bob Energy choke and kill manifolds are designed for use in the harshest of offshore environments.

All choke and kill manifolds and their component parts are manufactured under highly regulated industry product design and type approvals. All systems are fully certified in accordance with industry regulations and are witness tested by either ABS or DNV and certified for use accordingly. High pressure and high temperature are commonplace in todays’ offshore wells and drilling applications. All of our drill floor manifold, including choke and kill, have a proven track record in these environments.

Bob engineers have years of experience in the design, project management and manufacture of high-pressure manifolds including choke and kill, mud, cement, wash down and well test manifolds. Our engineers have worked on a wide variety of manifold packages including several for high-pressure high temperature (HPHT) 6th generation semi-subs, designed to deal with the harshest offshore drilling environments in the world.

This vast experience combined with the very latest in 3D modelling software means Bob provide unparalleled quality of service when supplying the perfect choke and kill manifold system for your needs. Bob will work closely with you from the initial design stages right through to the finished product ensuring you have a manifold individually tailored to meet your exact specification.

Industrial Standards for Choke and Kill Manifolds

Bob choke and kill manifolds and control systems can be designed and manufactured in accordance with any required industry standard. We have an in depth knowledge of all recognised industry standards, including:

- API 6A

- API 16C

- API RP-53

- ASME B31.3

- All applicable NORSOK and NPD regulations

- DNV-OS-E101

- DNV-OSS-201

- ABS CDS and many more.

We can obtain design reviews, inspection release certificates and product certificates from any third party classification society required by the project.

High-Pressure Forged Manifold Fittings for Choke and Kill Manifolds

Bob Energy only supplies the highest quality manifold fittings manufactured in the UK from wrought steel forgings – far superior to steel casings or steel plate. The fittings have been designed to meet all of the following international standards:

- MSS ‐ SP75: Specifications for High test Wrought Butt Weld Fittings.

- ANSI B31.3 Chemical Plant and Petroleum Refinery Piping.

- ANSI 16.9 Factory made Wrought Steel Bu tt Weld Fittings.

- NACE MR ‐ 01 ‐ 75 Sulphide Stress Cracking Resistant Metallic Materials for Oil Field Equipment.

- ASME VIII Division 1 section 13.10 Boiler and Pressure Vessel Code.

- API 6A Specifications for Wellhead and Christmas Tree Equipment

Bob forged manifold fittings for choke and kill manifolds are available for the following pressure ratings:

| MAX WORKING PREESSURE* | 5,000psi | 10,000psi | 15,000psi |

|---|---|---|---|

| Test pressure | 10,000psi | 15,000psi | 22,500psi |

| Material |

Carbon Manganese Steel (ASTM A860 Gr WPHY 52) |

Low Alloy steel (AISI 4130) |

Low Alloy steel (AISI 4130) |

| Min Yield | 52,000psi | 85,000psi | 85,000psi |

| Operating temps | ‐46 to 204 deg C | ‐46 to 204 deg C | ‐46 to 204 deg C |

Working pressures can be affected by a number of factors such as butt weld prep sizes. Please contact Bob for specific working pressures.

All tees and crosses can be supplied with reducing connections, these may effect the sizes of these fittings, please contact Bob for clarification.

See the tables in our Technical Data Book (available to download from our website) for the dimensional data of standard Bob choke and kill manifold fittings.

Please note that these are lists of only the most common sizes stocked by Bob. If you have any requirements for specific sizes or special materials that are not in the lists please contact sales@bobenergy.co.uk and we will be more than happy to assist.

Categories

- Choke & Kill Manifolds

- Mud Standpipe Manifolds

- Cement Manifolds

- 7500Psi Mud Gate Valves

- Choke Valves

- API 6A Gate Valves

- API 6A Cement Plug Valves

- API 6A Flanges & Fittings

- API 16A & API 16C Hubs & Clamps

- Long Sweep Manifold Fittings

- 4130 Compact Block Type Fittings

- 3D Double Back Fittings

- Hammer Lug Unions

- 4130 Seamless Pipe

Latest News

- Brent Crude Oil2016-01-09

Contact Us

Contact: Bob Smith

Phone: +44 (0) 1635 660788

Tel: +44 (0) 1635 660788

Add: Unit 28 Galloway Centre, Express Way, Newbury, RG14 5TL, United Kingdom